Motorcycle helmets are crucial for protection during crashes. They absorb impacts to protect your head and face, reducing injuries and fatalities. The right materials greatly enhance a helmet’s effectiveness. Safety equipment like helmets saves lives. The manufacturing process involves several detailed steps to meet safety standards. This guide explores how is a motorcycle helmet made.

The process starts with designing a helmet that protects the rider’s head during accidents. High-quality safety gear is crucial. I’ve been using helmets for years, and learning about their construction has been fascinating. Most of the procedure is done by hand and is incredibly detailed.

These products are crafted carefully, and the difference between an expensive and a cheaper helmet is significant. Seeing this firsthand was a fascinating experience and gave me a new appreciation for the craftsmanship involved.

Step-by-Step Guide to Helmet Manufacturing

Composite helmets are crafted by mixing materials like carbon and glass fibers, layering them in a criss-cross pattern within a mold, binding them with epoxy resin, and heating the mixture for a durable outer shell. This process is repeated to complete the helmet.

Choosing the Right Materials

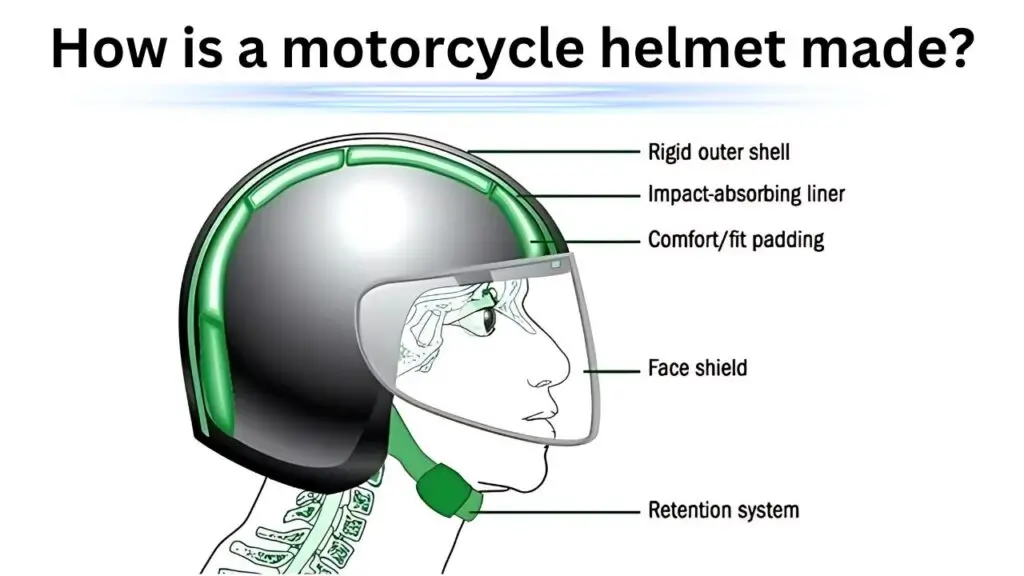

Selecting the right materials is essential for safety and comfort. The outer shell is made from tough substances like polycarbonate, fiberglass composite, or carbon fiber. Fiberglass is popular for its strength and affordability. It consists of glass fibers bound with epoxy resin, providing a balance of strength and flexibility. Carbon fiber, while more expensive, offers superior strength and lightness. Adding Kevlar enhances protection, as it’s incredibly strong, often blended with carbon for lighter, impact-resistant helmets. The outer shell handles impacts, while the inner liner absorbs energy. Expanded polystyrene (EPS) foam, molded into layers with differing densities, enhances shock absorption. Multi-density foam optimizes comfort and protection, ensuring a snug fit and keeping riders cool.

Molding the Outer Shell

The outer shell is formed through injection molding or the pre-preg technique. In injection molding, materials are heated and injected into a precise helmet mold. The pre-preg technique uses pre-coated materials for greater accuracy, ensuring durability and rider comfort.

Creating the Inner Shell

The inner shell, made from EPS foam, consists of several layers with varying densities to absorb different impact energies. Each layer is molded to fit the outer shell, enhancing safety and comfort.

Attaching the Face Shield

The visor protects your eyes from debris while ensuring visibility. Made from high-strength plastics, visors resist fogging and scratches, affixed securely to the helmet with adjustable mechanisms for a trusted fit.

Customizing the Look of the Helmet

Customization involves graphics and designs that improve visibility, crucial for safety. You can customize a helmet with hand-painted graphics or water decals, followed by a protective clear coat for a shiny finish. A personalized design can make a helmet stand out and help prevent accidents.

Ventilation Systems: A Breath of Fresh Air

Effective ventilation systems enhance comfort, especially on hot days. Vents are integrated into the shell during molding, with adjustable covers for airflow control, improving the overall riding experience.

Ensuring Helmet Safety with Straps and Buckles

A helmet must stay securely on your head, especially during collisions. The chin strap, made from durable materials like nylon or polypropylene, is firmly attached to the shell, ensuring the helmet remains in place. A well-fitted helmet with quality straps can make all the difference in an emergency.

The Final Stage: Quality Testing

Before reaching the market, helmets undergo stringent quality testing to meet safety standards. This includes impact, penetration, retention, and field-of-vision testing. Only helmets passing these tests make it to store shelves, ensuring rider safety. Riders should also be aware of the helmet brands to avoid, as not all products offer the same level of protection. Additionally, if you have a larger head, make sure to select a bigger helmet that still meets safety standards.

How Are Motorcycle Helmets Tested?

Testing motorcycle helmets is crucial for ensuring safety. For every thousand helmets produced, five are put through rigorous testing for impact protection and penetration resistance. One dramatic test involves dropping a helmet onto a sharp anvil from a height to simulate a real fall, showcasing how important it is to wear a helmet. Additionally, visors are shot at with air-gun pellets to check their impact resistance.

To further enhance performance, companies like Shoei use wind tunnels to assess aero dynamics and noise levels. This careful testing process helps ensure that helmets not only look good but also protect riders effectively during real-life incidents. The combination of impact tests and wind tunnel evaluations gives riders the confidence that their helmets will perform well on the road.

Find the Best Motorcycle Helmets.

When searching for the best motorcycle helmets, you want a magic combination of strength, flexibility, and lightness. Composite materials provide this balance, offering high protection, but they often come with a higher price tag. If you’re looking for something more affordable, plastic helmets are available, though they may be larger and heavier to compensate for their relative weakness.

Conclusion

Creating a motorcycle helmet is a careful and detailed process that prioritizes safety and comfort. The design phase uses advanced tools to ensure the helmet is strong and fits well. The outer shell is crafted from special materials like composite or plastic, providing strength without adding excessive weight. Once the outer shell is formed, an inner liner is added to absorb impacts, enhancing protection during accidents.

Rigorous testing follows to ensure the helmet meets safety standards. This includes assessing its resistance to impacts and penetration. Manufacturers typically test five helmets out of every thousand to evaluate their performance. Understanding how a helmet is made highlights the importance of wearing a high-quality helmet every time you ride. Your helmet is essential for protecting your head and ensuring a safer riding experience.

FAQs

About the Author

I am Daniel Ken, an experienced motorcycle rider with 8 years on the road, and I specialize in writing about motorcycle helmets. I share expert insights on helmet safety, comfort, and style, helping fellow riders choose the best gear. My knowledge covers top safety standards, helmet types, premium materials, and advanced ventilation and noise reduction features.